Disclosure: I am compensated for purchases made through some links on this site. Click for details.

When water invades a property, whether through flooding, leaks, or as a consequence of firefighting efforts, it sets the stage for immediate and long-term problems. Quick and effective water damage restoration is vital to prevent the escalation of damage, including the growth of mold, which thrives in damp environments. Similarly, mold restoration is a critical process aimed at removing existing mold and preventing its return, ensuring a safe and healthy indoor environment.

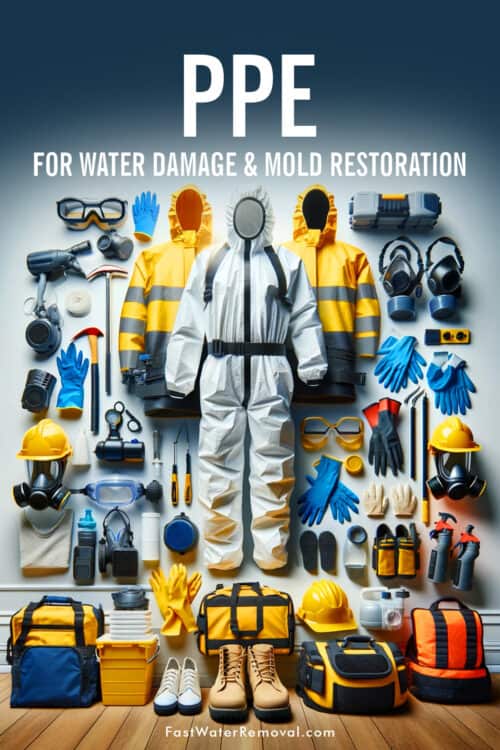

The inherent risks associated with these restoration efforts underscore the importance of using appropriate Personal Protective Equipment (PPE). From direct contact with contaminated water to exposure to potentially toxic mold spores, the dangers are real and varied. The right PPE shields restoration workers from these hazards, allowing them to perform their duties effectively and safely.

This guide delves into the specifics of PPE for water damage and mold restoration, covering the essential gear required and best practices for its use. Whether you are a seasoned restoration professional or new to the field, understanding these safety measures is paramount to protecting yourself and others during the restoration process. Let’s begin by examining the general PPE requirements for all restoration projects, setting the foundation for a deeper exploration into the unique needs of water damage and mold remediation efforts.

Key Takeaways

- The Importance of PPE: Understanding the vital role that PPE plays in protecting workers from the specific hazards encountered in water damage and mold restoration projects.

- Customized Protection: Recognizing the need for both general and specialized PPE to address the unique challenges of each restoration scenario.

- Safety Protocols: Emphasizing the significance of proper putting on, taking off, maintenance, and hygiene practices to maximize the effectiveness of PPE.

- Compliance and Health: Highlighting the legal requirements and health considerations that underpin the use of PPE in the restoration industry.

- Advancements in Safety Equipment: Looking forward to the integration of advanced technologies and smart PPE to enhance safety and efficiency on the job.

Understanding Water Damage and Mold Restoration

Before delving into the specifics of Personal Protective Equipment (PPE), it’s essential to grasp the core aspects of water damage and mold restoration. Each type of restoration addresses different challenges and risks, necessitating a tailored approach to safety and equipment.

Water Damage Restoration

Water damage can manifest in many forms, from localized flooding and burst pipes to widespread natural disasters. The primary goals in water damage restoration include removing standing water, drying out affected areas, and repairing or replacing damaged materials. This process not only restores the property to its pre-damage state but also prevents secondary issues like mold growth.

Risks associated with water damage restoration:

- Contaminated water exposure: Water from floods or sewage backups may contain harmful bacteria, viruses, and other pathogens.

- Electrical hazards: Water contact with electrical systems poses a risk of shocks or fires.

- Structural damage: Saturated materials can weaken structures, leading to collapses or falls.

Mold Restoration

Mold restoration focuses on identifying, containing, and removing mold growth within a property. It also involves taking measures to address the moisture source that allowed the mold to thrive initially. Effective mold remediation ensures a healthy living or working environment and prevents the recurrence of mold issues.

Risks associated with mold restoration:

- Health effects from mold exposure: Mold spores can cause allergic reactions, respiratory issues, and other health problems, especially in sensitive individuals.

- Cross-contamination: Without proper containment, mold spores can spread to unaffected areas, complicating the restoration process.

- Chemical exposure: The use of antimicrobial and cleaning agents requires careful handling to avoid skin, eye, or respiratory system irritation.

Understanding these key aspects and associated risks of water damage and mold restoration sets the stage for a discussion on the general PPE requirements for restoration projects. Safety protocols and the right equipment are fundamental to mitigating these risks, protecting restoration workers, and ensuring the successful completion of restoration tasks.

General PPE Requirements for Restoration Projects

Personal Protective Equipment (PPE) serves as the first line of defense against the various hazards encountered during water damage and mold restoration projects. While specific PPE requirements may vary depending on the task at hand, certain items are universally essential. This section outlines the general PPE that restoration professionals should equip themselves with, regardless of whether they are addressing water damage or mold.

Comprehensive Personal Protective Equipment List

- Gloves: Protection for the hands is crucial, as they are frequently in contact with contaminated materials, water, and chemicals.

- Types: Nitrile gloves for chemical resistance; latex or rubber gloves for water-related tasks.

- Materials: Selection depends on the task; use heavy-duty gloves for handling sharp or rough materials.

- Respirators: Respiratory protection is necessary to prevent inhalation of harmful particles, including mold spores, dust, and other airborne contaminants.

- N95 Masks: Suitable for basic filtration of particulates.

- Half-Face Respirators with P100 Filters: Recommended for higher protection levels, especially during mold remediation or when dealing with significantly contaminated environments.

- Goggles: Eye protection is essential to prevent irritation or injury from airborne particles, chemical splashes, or hazardous materials.

- Types: Encapsulating goggles offer full protection; non-encapsulating (safety glasses) for less intensive tasks.

- Protective Suits: Full-body protection against contaminants, chemicals, and water.

- Disposable vs. Reusable: Disposable suits are preferred for high-contamination environments; reusable suits can be used for less hazardous tasks.

- Footwear: Proper shoes or boots are critical for safety and comfort.

- Features: Waterproof, slip-resistant, and possibly steel-toed for environments with heavy debris.

- Hard Hats: For areas with a risk of falling debris or during demolition work, head protection is a must.

Choosing the Right Personal Protective Equipment

Selecting the appropriate PPE is not just about grabbing any protective item; it requires careful consideration of the specific hazards present in the work environment. For example, the type of gloves or respirator needed can vary greatly depending on whether the primary risk is chemical exposure, sharp objects, or airborne particulates.

Considerations for PPE Selection:

- Assess the Risk: Identify the specific hazards of the restoration project (chemical, biological, physical).

- Fit and Comfort: Properly fitting PPE is more likely to be worn correctly and consistently. Comfort also plays a role in worker compliance.

- Compliance with Standards: Ensure that all PPE meets the relevant safety standards and regulations, such as those set by OSHA or NIOSH.

Maintenance and Hygiene

- Regular Inspection: PPE should be inspected before and after each use for signs of wear or damage.

- Cleaning and Disposal: Follow manufacturer guidelines for cleaning reusable PPE. Disposable items should be disposed of properly after use.

- Hygiene Practices: Proper putting on and taking off procedures are essential to prevent cross-contamination.

Adhering to these general PPE guidelines ensures that restoration professionals are protected from a wide range of hazards. However, specific tasks such as water damage or mold restoration may require additional or specialized protective gear, as outlined in the following sections.

Specific PPE for Water Damage Restoration

Water damage restoration poses unique challenges and risks, particularly from contaminated water and damp environments. The Personal Protective Equipment (PPE) required for these tasks not only needs to protect against general hazards but also provide specific protection against moisture and waterborne pathogens. Here’s a detailed look at the specialized gear for water damage restoration.

Waterproof Clothing and Gear

- Purpose: To prevent soaking and protect against hypothermia in wet conditions.

- Items: Waterproof overalls or suits, and waterproof jackets.

Specialized Gloves

- Purpose: To protect hands from contaminated water that may contain chemicals, bacteria, or other hazardous substances.

- Types: Nitrile gloves offer chemical resistance, while thicker, more durable gloves provide protection against both contaminants and physical hazards.

Waterproof and Cut-Resistant Boots

- Purpose: To ensure foot protection against standing water and sharp objects hidden beneath the water.

- Features: Boots should be waterproof to keep feet dry and have a cut-resistant and slip-resistant sole to prevent injuries.

Safety Helmets with Visors

- Purpose: To protect the head from falling debris and the face from splashes.

- Types: Helmets with integrated visors or face shields offer dual protection, which is essential in environments with overhead hazards and splash risks.

Goggles or Face Shields

- Purpose: To protect eyes from contaminated water splashes.

- Selection: Goggles for tight sealing around the eyes or full face shields for broader facial protection.

Hearing Protection

- Purpose: Use in environments where high-powered drying equipment creates excessive noise.

- Types: Earplugs or earmuffs, depending on the level of noise and personal comfort.

Choosing the Right Water Damage Restoration Personal Protective Equipment :

- Assess the Contamination Level: The level of water contamination (clean, gray, or black water) will dictate the extent of protection needed.

- Environment: Consider the work environment’s specific challenges, including confined spaces that may require more compact PPE.

- Duration of Exposure: Longer tasks may require more durable and comfortable PPE to ensure ongoing protection and compliance.

Maintenance and Hygiene Tips:

- Decontamination: Properly clean and disinfect reusable gear after exposure to contaminated water.

- Dry Storage: Ensure all PPE is thoroughly dried before storage to prevent mold and mildew growth.

- Regular Inspection: Check for damage or wear, especially in waterproofing components, to maintain effective protection.

The PPE listed for water damage restoration not only ensures the safety of restoration professionals but also helps maintain a high level of efficiency and effectiveness in their work. Next, we will explore the specific PPE necessary for mold restoration, which requires additional precautions due to the airborne nature of mold spores.

Specific PPE for Mold Restoration

Mold restoration work involves unique challenges, primarily due to the need to protect against airborne spores that can have health implications. The Personal Protective Equipment (PPE) required for mold remediation is designed to prevent inhalation, ingestion, and skin contact with mold and its spores. Here’s a closer look at the specialized protective gear used in mold restoration.

HEPA Filter Respirators

- Purpose: To filter out mold spores from the air, preventing them from being inhaled by the worker.

- Types: Half-face or full-face respirators equipped with HEPA filters are recommended, depending on the level of mold exposure.

Full-Face Respirators

- Purpose: Offers comprehensive protection for the eyes, nose, and mouth against mold spores.

- Application: Essential for extensive mold removal tasks or in environments with high concentrations of airborne spores.

Protective Suits

- Purpose: To prevent mold spores from coming into contact with skin or personal clothing, which could lead to cross-contamination.

- Specifications: Disposable, impermeable suits are preferred, covering the entire body, including head and shoes.

Gloves

- Material: Nitrile gloves are recommended for their resistance to tears and punctures, as well as their ability to prevent skin contact with mold and cleaning chemicals.

- Use: Must be worn at all times during mold remediation to handle contaminated materials safely.

Goggles

- Purpose: To protect eyes from mold spores and cleaning agents.

- Selection: Goggles that form a seal around the eyes are preferred to prevent entry of spores.

Footwear

- Requirements: Waterproof and slip-resistant boots, preferably with a steel toe, to protect against physical hazards in the work area.

- Hygiene: Footwear should be decontaminated after use or covered with disposable boot covers to prevent spore spread.

Selecting the Appropriate Mold Restoration Personal Protective Equipment :

- Assess Mold Exposure Level: The extent of mold growth and the type of mold present can influence the level of PPE required.

- Consider the Environment: Enclosed spaces may require more stringent protection due to limited ventilation.

- Understand the Task: Different stages of mold remediation (e.g., removal, cleaning, and disinfection) may require adjustments in PPE.

Maintenance and Hygiene Tips:

- Cleaning: Non-disposable items like respirators and goggles should be cleaned and disinfected according to manufacturer instructions.

- Inspection: Regularly check for signs of wear or damage, particularly in items that seal out contaminants, like respirators and goggles.

- Storage: Store PPE in a clean, dry area to prevent contamination or degradation of materials.

Proper use of PPE in mold restoration not only protects the health of the workers but also contributes to the effectiveness of the remediation process. By preventing the spread of spores and ensuring safe handling of mold-contaminated materials, restoration professionals can successfully restore environments to safe, mold-free conditions.

Next, we will explore safety protocols and best practices that complement the use of PPE, ensuring a comprehensive approach to safety in both water damage and mold restoration projects.

Safety Protocols and Best Practices

Implementing safety protocols and best practices is essential for maximizing the effectiveness of Personal Protective Equipment (PPE) in water damage and mold restoration projects. These guidelines not only enhance the safety of the restoration team but also ensure a thorough and responsible approach to remediation work. Below are key safety protocols and best practices tailored to the unique demands of restoration projects.

Protocols for Putting On and Taking Off PPE

Putting On PPE:

- Inspect: Before wearing, inspect PPE for damage or defects.

- Clean Hands: Always start with hand hygiene, using soap and water or hand sanitizer.

- Sequence: Follow a proper sequence, typically starting with inner layers (like respirators and goggles) and ending with outer layers (such as gloves and protective suits).

- Fit Check: Ensure a proper fit, especially for respirators, to ensure they seal correctly.

Taking Off PPE:

- Sequence: Remove PPE in a sequence that minimizes the potential for contamination. Gloves are usually the first to be removed, followed by goggles, suits, and respirators.

- Avoid Contact: Be careful not to touch the outer surfaces of the PPE.

- Hand Hygiene: Perform hand hygiene after removing each item of PPE.

- Dispose or Disinfect: Properly dispose of disposable items or clean and disinfect reusable items according to guidelines.

Hygiene Practices to Prevent Cross-Contamination

- Separate Clean and Contaminated Areas: Designate specific zones for putting on and taking off PPE to minimize cross-contamination.

- Regular Cleaning and Disinfection: Regularly clean surfaces and equipment with appropriate disinfectants, especially in areas where PPE is put on and taken off.

- Personal Hygiene: Encourage regular handwashing and the use of hand sanitizer, particularly after removing PPE or handling contaminated materials.

Regular PPE Inspection and Maintenance

- Scheduled Inspections: Incorporate regular checks of all PPE for signs of wear, tear, or failure.

- Maintenance Records: Keep records of PPE maintenance, including cleaning, inspection, and repair, to ensure compliance and safety.

- Immediate Replacement: Replace any PPE that is damaged or no longer provides adequate protection immediately.

Training and Awareness

- Comprehensive Training: Ensure all team members are trained in the proper use, maintenance, and disposal of PPE, as well as in the specific safety protocols for water damage and mold restoration.

- Updates on Best Practices: Keep the team informed about the latest safety recommendations, PPE innovations, and regulatory changes.

- Encourage Communication: Promote a culture where team members feel comfortable reporting potential safety concerns and suggesting improvements.

Safety Equipment Checks

- Pre-Work Checks: Before starting any restoration task, conduct a thorough check of all required safety equipment.

- Emergency Kits: Maintain readily accessible emergency kits, including first aid supplies, eyewash stations, and spill cleanup materials.

Implementing these safety protocols and best practices ensures that restoration professionals are not only protected from the immediate hazards of water damage and mold but also from the long-term health risks associated with these challenging tasks. By prioritizing safety and preparedness, restoration teams can work efficiently and effectively, restoring properties to their pre-damage condition while safeguarding their health and well-being.

Next, we will discuss the legal and health considerations surrounding the use of PPE in restoration projects, highlighting the importance of compliance with safety regulations and awareness of health impacts.

Legal and Health Considerations

When engaging in water damage and mold restoration projects, legal and health considerations are paramount. Compliance with safety regulations not only ensures the well-being of restoration professionals but also protects property owners and the general public. This section outlines key legal guidelines and health implications related to the use of Personal Protective Equipment (PPE) and safe restoration practices.

Overview of OSHA Guidelines

The Occupational Safety and Health Administration (OSHA) sets forth standards that must be followed to protect workers from harm. These guidelines cover a range of requirements, including:

- PPE Standards: Specific requirements for the type, use, and maintenance of PPE to protect against various hazards encountered in restoration work.

- Hazard Communication: Requirements for informing workers about the chemical hazards they may face, including the use of Safety Data Sheets (SDS) and proper labeling.

- Respiratory Protection: Protocols for when and how to use respirators, including necessary fit testing and medical evaluations.

- Training Requirements: Mandates for employer-provided training on the correct use of PPE and understanding of workplace hazards.

Health Considerations and Precautions

The health risks associated with water damage and mold restoration can be significant, ranging from immediate allergic reactions to long-term respiratory issues. Key health considerations include:

- Exposure to Contaminants: Direct contact with contaminated water, mold, and chemicals can lead to skin irritation, infections, or more serious health conditions.

- Respiratory Health: Inhalation of mold spores, dust, and other particulates can exacerbate or lead to respiratory conditions, emphasizing the importance of effective respiratory protection.

- Stress and Fatigue: The physically demanding nature of restoration work can lead to overexertion and stress-related health issues, highlighting the need for proper rest, hydration, and ergonomics.

Importance of Proper Ventilation and Air Filtration

- Reducing Airborne Contaminants: Use of air scrubbers and negative air machines to remove particulates and mold spores from the air, protecting both workers and building occupants.

- Maintaining Indoor Air Quality: Ensuring adequate ventilation during and after the restoration process to prevent the accumulation of hazardous substances.

Compliance and Record-Keeping

- Documentation: Maintaining records of training, incident reports, and PPE maintenance to demonstrate compliance with OSHA standards and other regulations.

- Regular Audits: Conducting periodic audits of safety practices and PPE use to identify areas for improvement and ensure ongoing compliance.

By adhering to legal guidelines and being cognizant of health risks, restoration professionals can safeguard not only their own health and safety but also that of their colleagues and the communities they serve. This comprehensive approach to safety and compliance facilitates effective and responsible water damage and mold restoration practices.

The next and final section of this guide will explore advanced PPE and technologies that enhance safety in restoration work, offering insights into the future of restoration safety equipment.

Advanced PPE and Technologies

The field of water damage and mold restoration is constantly evolving, with advancements in Personal Protective Equipment (PPE) and technology playing a significant role in enhancing worker safety and project efficiency. This section explores cutting-edge PPE and innovative tools that are setting new standards for protection and performance in the restoration industry.

Smart PPE

Integration of Technology: Modern PPE now incorporates technology to improve safety and functionality. For example, smart helmets with built-in communication systems allow for better coordination among team members in noisy environments or while wearing full-face respirators.

Health Monitoring Features: Some PPE items come equipped with environmental and biometric sensors. These can monitor heart rate, temperature, and exposure to hazardous substances, providing real-time data to prevent overexertion and ensure workers are not exposed to dangerous levels of contaminants.

Advanced Respiratory Protection

Powered Air-Purifying Respirators (PAPRs): These respirators offer an enhanced level of protection and comfort, especially in environments with high concentrations of airborne contaminants. PAPRs use a battery-powered blower to pass air through filters, delivering clean air to the wearer.

Full-Face Respirator Masks with Integrated Communication Devices: These allow for clear communication without removing the mask, crucial in maintaining safety in hazardous environments.

High-Tech Protective Suits

Materials with Enhanced Properties: New materials offer not only impermeability to water and contaminants but also breathability, reducing heat stress and improving wearer comfort during long shifts.

Wearable Technology: Protective suits equipped with RFID tags or GPS trackers can enhance worker safety by monitoring location and vital signs, ensuring quick response in case of emergency.

Ergonomic and Impact-Resistant Footwear

Advanced Materials: Footwear designed for restoration work is now lighter, more durable, and offers better grip and protection against impacts, punctures, and slips, thanks to materials like Kevlar and advanced rubber compounds.

Built-in Sensors: Some boots come with pressure sensors and motion trackers to monitor the wearer’s posture and gait, helping to prevent musculoskeletal injuries.

Future Trends in Restoration Safety Equipment

Augmented Reality (AR) Goggles: AR technology can provide real-time information overlay, such as safety warnings, project details, and navigation through complex sites, directly in the wearer’s field of vision.

Robotics and Drones: These technologies are increasingly used for inspection and assessment of hard-to-reach or hazardous areas, reducing the need for physical entry by workers and thereby limiting their exposure to risks.

AI-Powered Hazard Detection: Artificial intelligence can analyze data from wearable sensors and environmental monitors to predict and alert workers to potential hazards, such as structural weaknesses or the presence of toxic substances.

As these advanced PPE and technologies become more integrated into the restoration industry, they promise to significantly improve the safety, efficiency, and outcomes of water damage and mold restoration projects. By staying abreast of these innovations, restoration professionals can better protect themselves and their teams while delivering high-quality, safe restoration services.

This exploration of PPE, from basic requirements to the latest innovations, underscores the critical role of safety equipment in protecting restoration workers. The commitment to safety, through proper equipment, training, and adherence to legal standards, is essential for the well-being of those on the front lines of restoration work and the communities they serve.

Conclusion

The extensive exploration of Personal Protective Equipment (PPE) for water damage and mold restoration has highlighted the crucial role that proper safety gear plays in protecting restoration professionals from the myriad of hazards they face on the job. From standard PPE requirements to specialized equipment for tackling specific challenges presented by water damage and mold, the importance of selecting, using, and maintaining the right protective gear cannot be overstated.

Key Points:

- General PPE Requirements: Essential gear, including gloves, respirators, goggles, protective suits, and footwear, provides foundational protection for all restoration projects.

- Specific Needs for Water Damage Restoration: Waterproof and durable gear protects against the unique challenges of water-related hazards, including contaminated water and slippery conditions.

- Mold Restoration Specifics: Advanced respiratory protection and full-coverage clothing are critical to safeguard against mold spores and the health risks they pose.

- Safety Protocols and Best Practices: Effective use of PPE is complemented by strict adherence to safety protocols, including proper putting on and taking off procedures, regular equipment inspections, and hygiene practices.

- Legal and Health Considerations: Compliance with OSHA guidelines and awareness of health implications underline the importance of a comprehensive safety strategy.

- Advancements in PPE and Technology: Emerging technologies and smart PPE promise to enhance safety and efficiency in restoration work, setting new standards for worker protection.

Additional Resources

To further support restoration professionals in their commitment to safety, consider exploring the following resources:

- OSHA Guidelines and Training Materials: Comprehensive information on safety standards and practices.

- PPE Manufacturers and Suppliers: Updates on the latest PPE innovations and products.

- Safety Training Workshops and Webinars: Opportunities for ongoing education and certification in restoration safety practices.

By embracing these resources and the principles outlined in this guide, restoration professionals can continue to safeguard their health and well-being, while delivering the vital services that help communities recover and thrive after water damage and mold challenges.